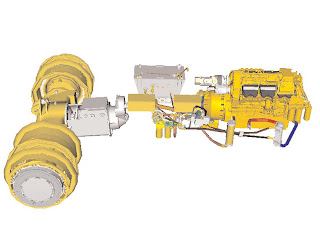

The 777F Off-highway Truck power train is electronically controlled. The Transmission/Chassis ECM controls the ECPC transmission shifting and the torque converter lockup clutch operation. The transmission has seven forward speeds and one reverse speed. Power flows from the engine to the rear wheels through the power train. The main power train components are:

- Torque converter (1)

- Drive shaft (2)

- Transfer gears (3)

- Transmission (4)

- Differential (5)

- Final drives (6)

Other power train components visible in this illustration are the transmission charge filters (7), torque converter charging filter (8), and two-section hydraulic tank (9).

These illustrations show the location of the main electronic components in the power train. The Transmission/Chassis ECM (1) is located behind the cab seat and is accessed by removing a panel at the rear of the cab. The transmission modulating valves (2) are located on top of the transmission planetary gears and are accessed by removing a cover plate. The torque converter lockup clutch solenoid valve (3) is located on the rear of the torque converter.

NOTE: The Transmission/Chassis ECM receives input signals from several components located on the machine to control transmission shifting and the torque converter lockup clutch operation. The electronic components will be covered later in the presentation.

Shown is the transmission and torque converter hydraulic system for the 777F. A five section pump is located at the rear of the torque converter housing. The first section (attached to pump drive at rear of torque converter) scavenges oil from the bottom of the torque converter case and returns the oil to the hoist, torque converter, and brake hydraulic tank. The second section pumps charge oil through the torque converter filter to the torque converter. The third section sends oil through the lockup clutch filter and provides pilot oil to the following circuits:

- Lockup clutch valve

- Variable speed fan clutch control

- Hoist pilot signal resolver

- Traction control valve

The fourth section scavenges oil from the transmission sump and sends oil to the transmission oil cooler and the transmission hydraulic tank.

The fifth section sends charge oil through the transmission oil filters to the transmission control valves.

Torque Converter Hydraulic System

This schematic shows the oil flow from the torque converter pump through the torque converter hydraulic system.

The scavenge pump section pulls oil through a screen from the torque converter housing and sends the oil to the hoist, torque converter, and brake hydraulic tank.

The torque converter charging pump section sends oil through the torque converter charging filter to the torque converter inlet relief valve. Oil flows from the inlet relief valve through the torque converter to the outlet relief valve. Oil flows from the outlet relief valve to the brake oil cooling circuit.

The lockup clutch valve pump section sends oil through the lockup clutch valve filter to the torque converter lockup clutch valve. When oil pressure in the lockup clutch valve circuit is too high, the lockup clutch relief valve allows oil to flow to the brake cooling circuit.

Oil from the lockup clutch valve pump section also flows to the TCS valve, variable speed clutch control and hoist pilot signal resolver.

The five sections of the power train pump (from the front to the rear) are:

- Torque converter scavenge (1)

- Torque converter charging (2)

- Lockup clutch valve, hoist pilot circuit, TCS valve, and variable speed fan clutch (3)

- Transmission scavenge (4)

- Transmission charging (5)

The five sections of the power train pump (from the front to the rear) are:

- Torque converter scavenge (1)

- Torque converter charging (2)

- Lockup clutch valve, hoist pilot circuit, TCS valve, and variable speed fan clutch (3)

- Transmission scavenge (4)

- Transmission charging (5)

In DIRECT DRIVE, the lockup clutch is engaged by hydraulic pressure and locks the turbine to the impeller. The housing, impeller, turbine, and output shaft then rotate as a unit at engine rpm. The stator, which is mounted on a one-way clutch, is driven by the force of the oil in the housing. The one-way clutch permits the stator to turn freely in DIRECT DRIVE when torque multiplication is not required.

The five section power train pump (1) is located at the bottom rear of the torque converter.

The inlet relief valve (2) limits the maximum pressure of the supply oil to the torque converter.

The torque converter inlet relief pressure can be checked by removing a plug and installing a pressure tap. Normally, the inlet relief pressure will be slightly higher than the outlet relief valve pressure.

Oil flows through the inlet relief valve and enters the torque converter. Some of the oil will leak through the torque converter to the bottom of the housing to be scavenged. Most of the oil in the torque converter is used to provide a fluid coupling and flows through the torque converter outlet relief valve (3).

The outlet relief valve maintains the minimum pressure inside the torque converter. The main function of the outlet relief valve is to keep the torque converter full of oil to prevent cavitation. The outlet relief pressure can be measured at the tap (4) on the outlet relief valve.

The torque converter lockup clutch valve (5) directs oil to engage the torque converter lockup clutch. The torque converter lockup clutch pressure can be checked at the tap (6) on top of the lockup clutch valve.

Excess oil that accumulates in the bottom of the torque converter is scavenged by the first section of the pump through a screen behind the access cover (7) and returned to the hoist, torque converter, and brake hydraulic tank.

A torque converter outlet temperature sensor (arrow) provides an input signal to the Transmission/Chassis ECM, which sends a signal to the monitoring system to inform the operator of the torque converter outlet temperature.

Oil from the lockup clutch valve pump section flows to the lockup valve oil filter (1) and then to the lockup clutch modulating valve (2). The filter is located inside of the left frame rail.

The filter has a bypass switch (3) which provides an input signal to the monitoring system, via the Transmission/Chassis ECM, to inform the operator if the filter is restricted. The filter housing has an S•O•S tap (4) and a lockup clutch circuit pressure tap (5).

The lockup clutch relief valve (1) is located inside the left frame rail in front of the lockup clutch filter (2). This view is looking up from the bottom of the truck. When oil pressure in the lockup clutch valve circuit is too high, the lockup clutch relief valve allows oil to flow to the brake cooling circuit.

The torque converter charging filter (1) is located on the right frame rail, behind the right front tire. Oil from the torque converter charging pump section flowS through the torque converter filter to the torque converter inlet relief valve.

The torque converter filter includes an S•O•S port (2) located on the bottom of the filter.

See You Soon!!!

MARYGAR

0 comments:

Post a Comment